Whether you need Green-on-Brown or Green-on-Green detection, we’ve got you covered. Our system gives you ultimate flexibility and precision.

Take a look below to see what our clients say about our system and how it has improved their operations and savings.

Our Green-on-Brown technology can detect grass weeds and broadleaves in fallow or bare soil, using artificial intelligence and smart cameras. The system can be used at a speed of up to 25km/h and has a night vision option. Thanks to our spot-spraying solution, blanket spraying can be avoided and results in a reduction of herbicides use of 90% on average.

Our system has been commercialised since 2018 and we have since then installed several systems that are currently running in Australia & Europe.

More than 100 000 hectares have been sprayed already.

GREEN ON BROWN

detection on every type of soil

> 1 000 000 ha

> 90% average

hit ratio

> 90% average chemical savings

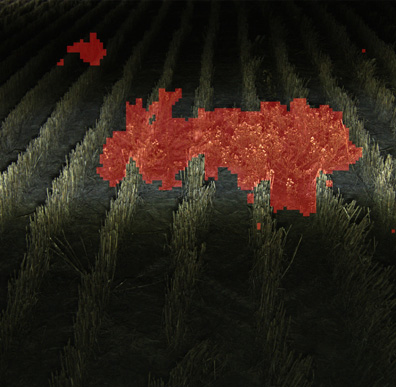

GREEN ON GREEN

smart system for weeds recognition

Bilberry have developed a smart spraying solution capable of detecting weeds in crop. Some examples of applications that Bilberry offer users include:

1. Cereal Application Booklet

2. Lupin Application Booklet

3. Canola Application Booklet

4. Blue Lupin in Lupin Application Booklet

5. Vetch in Lentil Application Booklet

6. Chickpea Application Booklet

7. Lentil Application Booklet

8. Cotton Application Booklet

9. Sorghum Application Booklet

Bilberry have developed these applications to work on farms all across Australia, Canada and some other regions globally.

For more information about applications available for your region contact us today!

> 300 000 ha

> 90% average

hit ratio

> 90% average chemical savings

MAPPING

Our mission does not stop with spraying. We want to make sure to provide you with the most data possible. Our system logs every weed detection and nozzle opening to provide an accurate mapping of all spraying sessions and field status.

Those maps, which are available on a dedicated web platform, can easily be integrated with the sprayers for further applications or in agricultural management software to improve field knowledge and make informed decisions.

At Bilberry, we value your input. If you have specific needs, feel free to contact us to discuss them in-depth.

TIMELINE

KEY BENEFITS OF SMART SPRAYING

Up to 98% chemical savings

Cut your chemical expenses by spraying only where weeds are.

Resistance management

Use more effective chemicals at a higher dose to get better weed control.

Sustainable

farming

Prolong herbicide life on your farm while helping the environment.

Reduce chemical exposure

By filling less, you will be less exposed to chemicals

Spray

fast

25 km/h (15 mph) maximum speed. Available on all boom sizes

Increase knowledge of your paddock

Generate and store weed maps of each spray to understand your paddock.

Reduce crop

damage

Increase yield by minimising unnecessary crop injury.

Reduce filling

time

By spraying 10 times

less, you will also fill up

10 times less.

TESTIMONIALS

DYSON FARMING SMART FARM, UNITED KINGDOM

“Green on Green was completely new to everybody so we were a little dubious. We did a trial and we were absolutely amazed by the results.” – Richard Lee.

GEORGINA FARMS, WESTERN AUSTRALIA

“The amount of chemical we are using (with the Bilberry system) is at best 5% but at worst it’s 20% of the usage that was there before.” – Gareth Rowe